Own Project 2: Orange Juicer Handle Repair

A project about using design in the real world for repairability.

This project of my own is where I used my design skills to repair an orange juicer machine. This orange juicer has a handle, which would break as it didn’t fit the support it was bolted to. This handle needed to be adapted to certain specifications and contain a magnet to activate the mechanism. A replacement part would cost 40 euros, which would have a high chance to break again. This project had a short time-frame to complete, as this machine is used in a restaurant. The project took a week to complete and is still in use today.

The orange juicer machine handle didn't fit correctly on the metal attachment point of the machine. This required the need for self-tapping screws to fasten the handle, destroying it in the process.

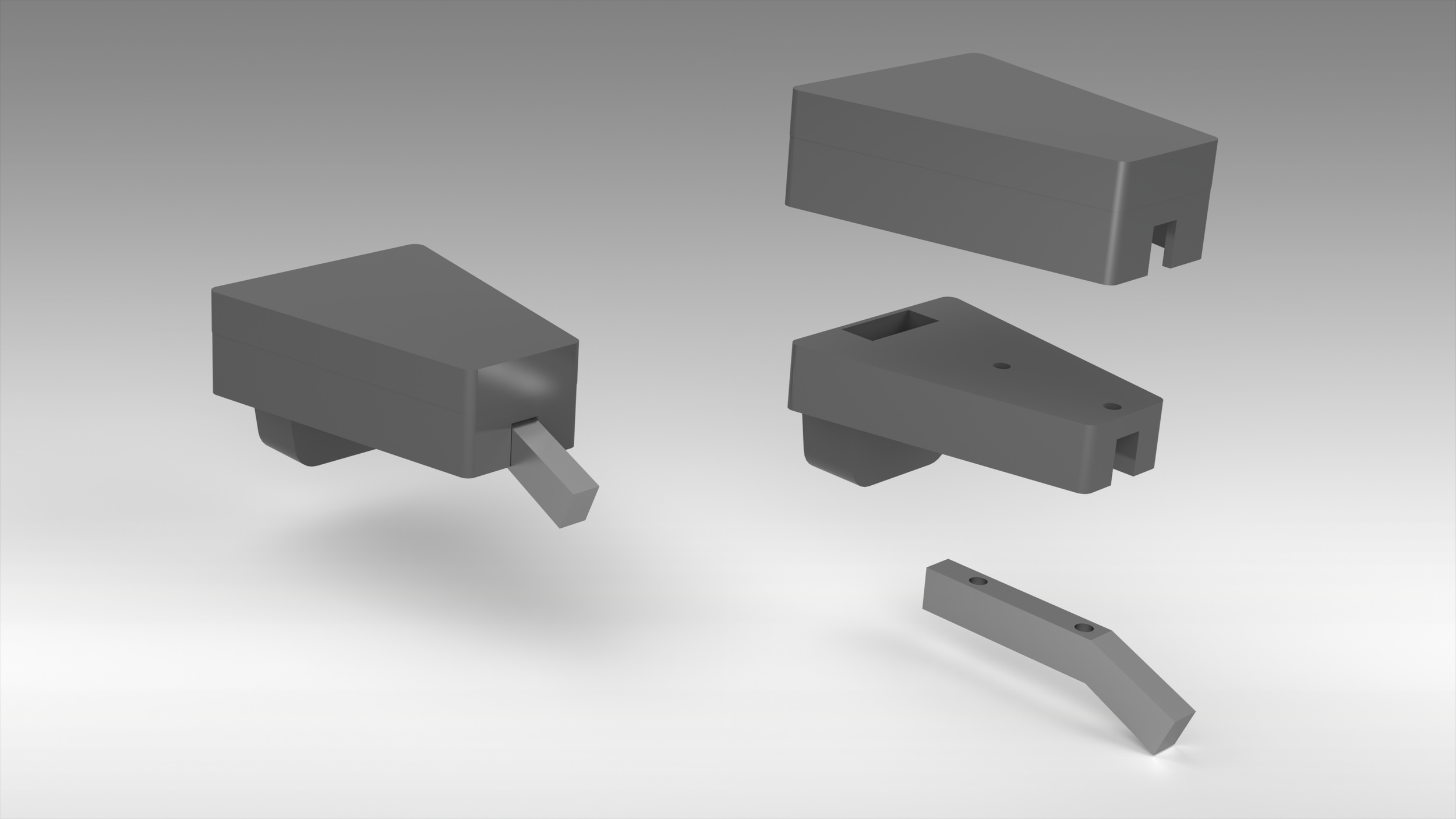

Within SolidWorks I created a prototype of the juice handle. One of the first features is the use of bolts to attach the handle to the machine. In order to hide the bolts, the threads were 3D printed. A number of iterations were created to test the feasibility of this technique.

One problem that arose during prototyping is a result of 3D printing thin walls on top of a solid. This caused a slight overhang on the handle. This was remedied through testing rapid prototypes and creating the correct offset within the model.

After perfecting the features through rapid prototyping and iterations, the juice handle was ready for production.

The juice handle worked perfectly and was made of sturdy PETG using 3D printing. The juice handle is still in use as of today three years later.